Your Position:

Home > Water Pumps

Chemical / Sea Water Pump Set

Flow Range:

100~3000m³/h

Application:

Petroleum, chemical, coal and other flammable and explosive, coastal areas and other environments.

Explosion-Proof Engine:

Cummins (original power)

Directive:

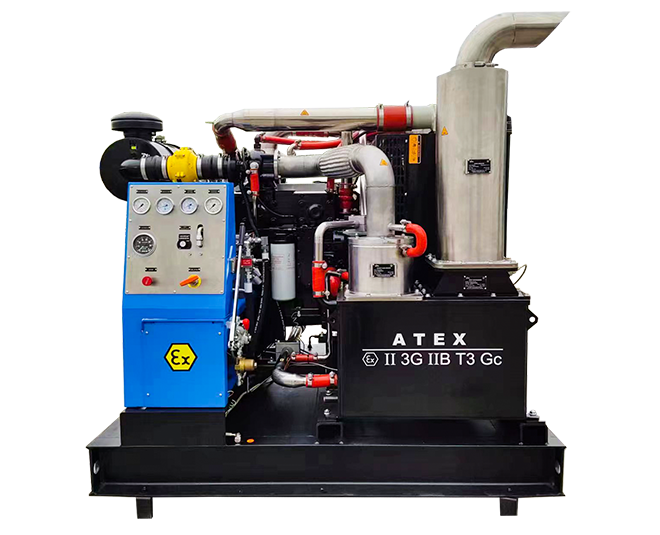

Implement the EU ATEX 2014/34/EU Directive and comply with the EU ATEX explosion-proof standards such as EN60079 series and EN1834 series.

Unit Type:

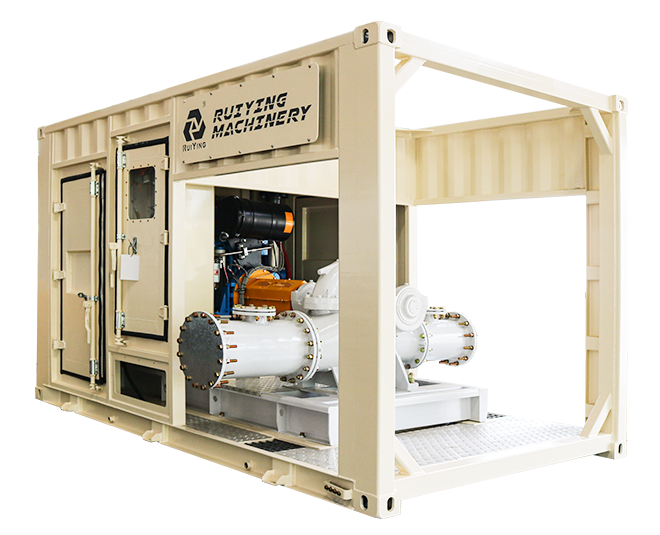

Fixed type ,Mobile type, Container type

Contact us if you need customized products!

Introduction

Product Video

Related Cases

Introduction

Chemical / Sea Water Pump Set

"Ruiying Manufacture" is a professional sustainable productivity and solutions provider, The equipment is composed of explosion-proof engine (the original power uses the international well-known brand Cummins engine), water pump, explosion-proof control box, explosion-proof battery, water inlet pipe, drainage pipes, rain-proof boxes,, explosion-proof fuel tank, public chassis or trailer chassis, etc., mainly with petroleum, chemical, coal and other flammable and explosive environment. The device controller can display Chinese, English, French, Russian and other languages, which can realize remote monitoring and remote control of the device.

Explosion-proof diesel engine is a kind of diesel engine specially designed for flammable and explosive environment, compared with ordinary diesel engine, it has higher safety and reliability.

If your site is in coastal areas where seawater corrosion and salt spray corrosion are serious, or the pumping medium is seawater, we will customize copper or corrosion-resistant stainless steel pumps for you.

Explosion-proof diesel engine is a kind of diesel engine specially designed for flammable and explosive environment, compared with ordinary diesel engine, it has higher safety and reliability.

If your site is in coastal areas where seawater corrosion and salt spray corrosion are serious, or the pumping medium is seawater, we will customize copper or corrosion-resistant stainless steel pumps for you.

Explosion-proof design:

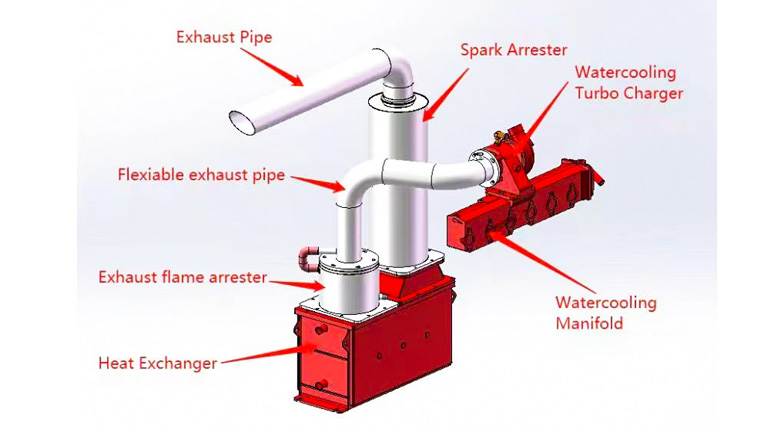

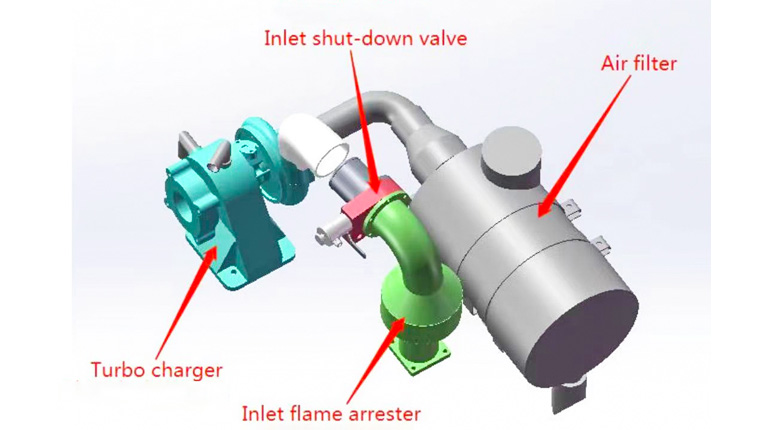

Explosion-proof diesel engines have a special explosion-proof design to enable them to operate safely in flammable and explosive environments. These designs include special fuel systems, intake systems, exhaust systems, electrical systems, etc., to prevent explosions caused by sparks and high temperatures.

Material selection:

The components and material selection of explosion-proof diesel engines should meet the explosion-proof requirements and be able to withstand explosion pressure and flame impact. This includes the use of explosion-proof materials to make components such as engine housings, fuel tanks, and oil tubing. Some materials should be made of anti-static materials to avoid electrostatic agglomeration discharge.

Control system:

Explosion-proof diesel engines are usually equipped with special control systems to ensure the safe operation of the engine in dangerous environments. These control systems can monitor the temperature, pressure, speed and other parameters of the engine, and take appropriate shutdown and alarm measures when necessary, such as shutting off the intake and fuel supply when the engine is speeding, to ensure that the engine can be reliably shut down in the first time.

Video

Related Video

The product consists of diesel engine, high-flow water pump, trailer chassis, intelligent control system, vacuum system, water inlet pipe, drainage pipe, rainproof box, etc. It is mainly used in farms and farmland irrigation in areas without power supply.

Get A Free Quote

Cases

Application Cases

OUR PRODUCT

Related Products